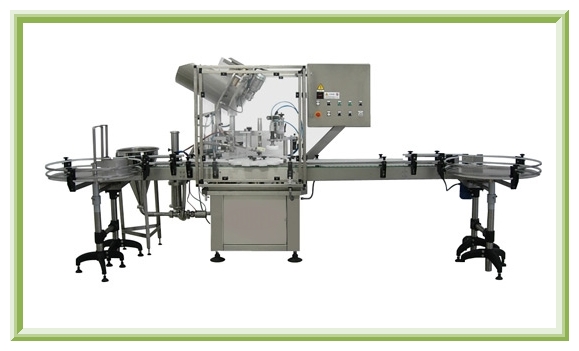

The RTW1000 automatic dosing+capping machine is designed for filling jars or bottles with thick food products and capping with twist-off caps.

Electrowelded stainless steel base, mounted on 4 adjustable supporting legs

All operations (filling, cap distribution, cap closing) take place on a rotary starwheel, with step-by-step motion

Channel around work surface to collect any discharged product

Complete machine designed for independent operation, supplied with stainless steel chain, transmission and drive.

Certified CE conformity.

Electric Control Panel with IP55 safety protection

Volumetric doser with gear pump :

no. 1 rotary pump made in aisi.316 quality stainless steel

inverter speed adjustment of the pump

adjustment of the product dose from 20cc and of the rotation speed by electronic setting on control panel

pneumatic controlled 2-ways nozzle with anti-dripping device

ideal for dense and partially dense products; it gives a higher precision in the dosing without pressure adjustments, thanks to the quick electronic adjustment.

Easy to wash and sterilize, reduced maintenance and wear.

Caps distributor and closer :

Capsule distributor with silent magnetic positioner for metal capsules

adjustable drop channel for different sizes, release head

device for detecting capsules in the channel

No. 1 screwing head, pneumatically operated at low speed with controlled closure stress

Hot-air heater for capsule rubber seal, before capsule release, with adjustable temperature control

Large diameter starwhel for jar motion to the different positions

PLC with touch-screen controller for adjusting

all working settings (start-stop, automatic-manual cycle, washing cycle, precision setting

of the dose, filling speed with flow adjustments, working timing “bottle stop – filling – start”, alarms display)