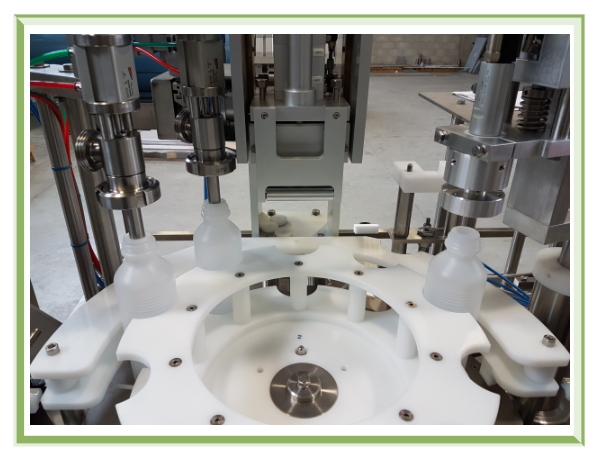

The series of 'RT-PK' monoblocks is designed for packaging of bottles and jars with plastic caps, pre-threaded screw or pressure models.

These machines may be highly customized with :

* Filling station, equipped with 1 - 2 - 3 or 4 dosing heds.

The filling method is volumetric, using Aisi 316 rotary gear pumps with electronic control by PLC and frequency inverter.

This technology gives the operator the full control on the working parameters, starting from the adjustment of the dose to the various time settings.

Filling of very thick or foamy products are easily allows using plunging (bottom-up) nozzles.

* Capping station, with precision cap dispensing (pick & place): the caps are picked up from the pick-off clamp by a transfer arm and released straight on the bottle mouth.

The caps are the sealed by one or two rotating or pressing heads.

* In addition or as alternative to the capping station, it is possible to add a heat-sealing head, to seal and cut film in roll.

The filling machines series 'RT-PK' are usually employed in the dairy industry (for yoghurt, probiotics, milk, cream) and in the canning industry (for tomato and meat sauces, mayonnaise, ketchup, syrups, dressings, spreads) in both jars and bottles,

These machines, as all our models, are mainly realized in stainless steel and food safe approved plastics.